Showcase

Check out our projects!

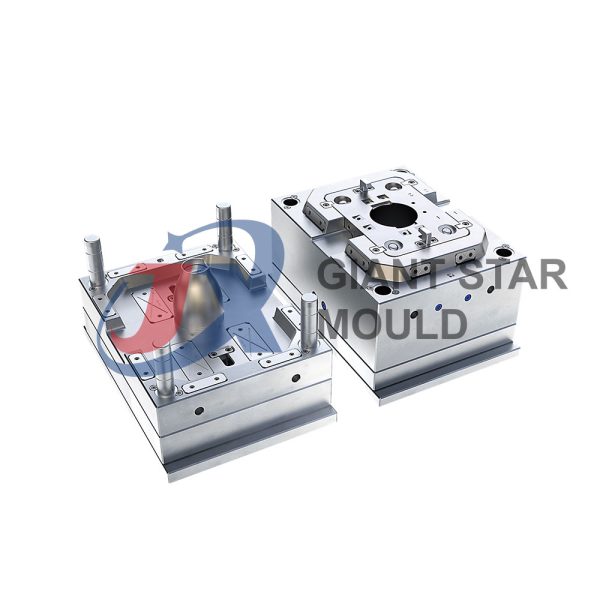

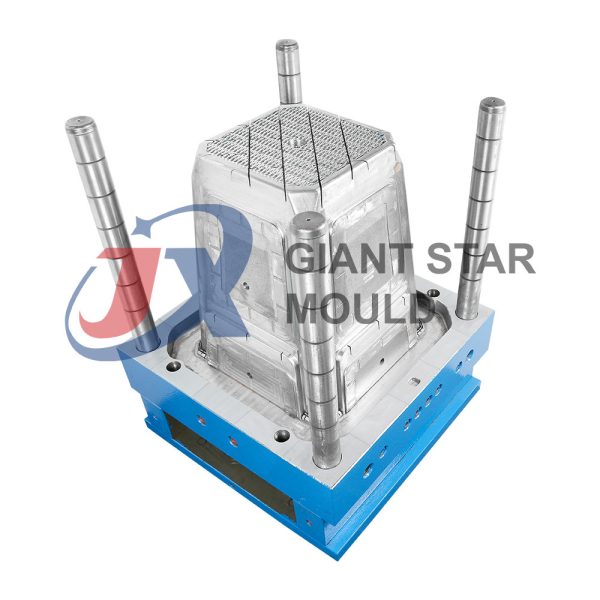

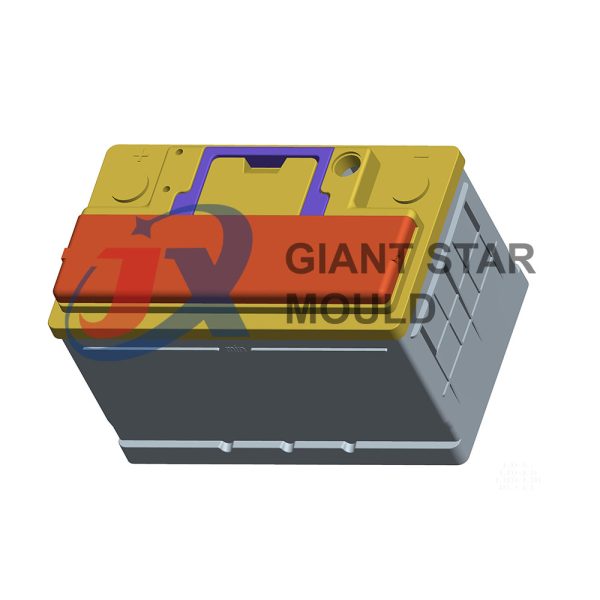

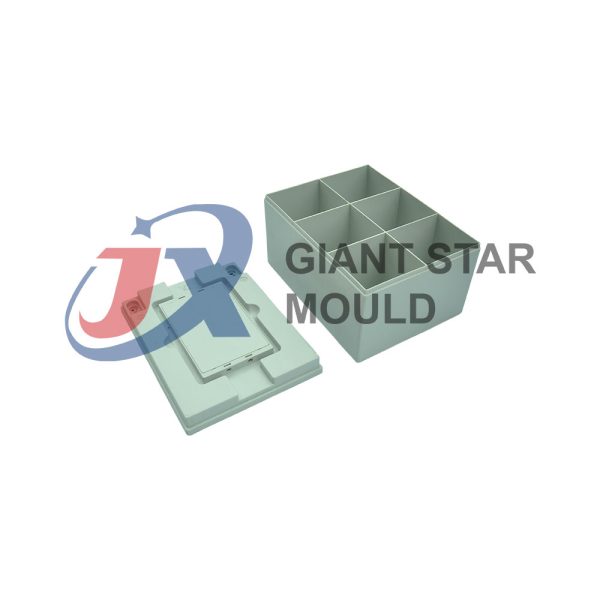

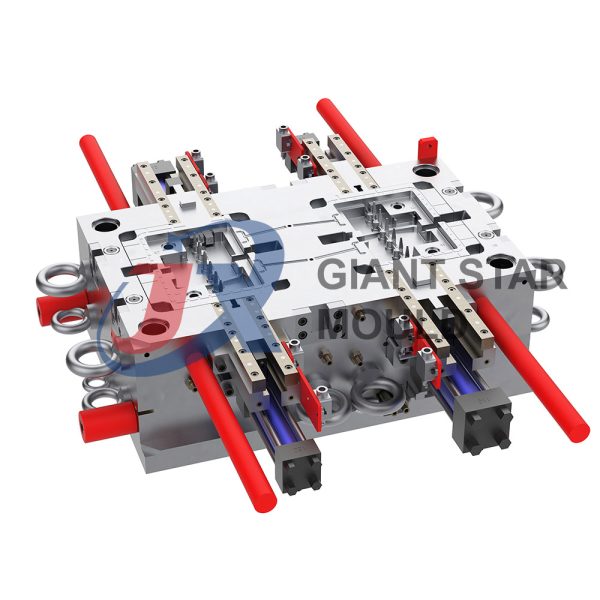

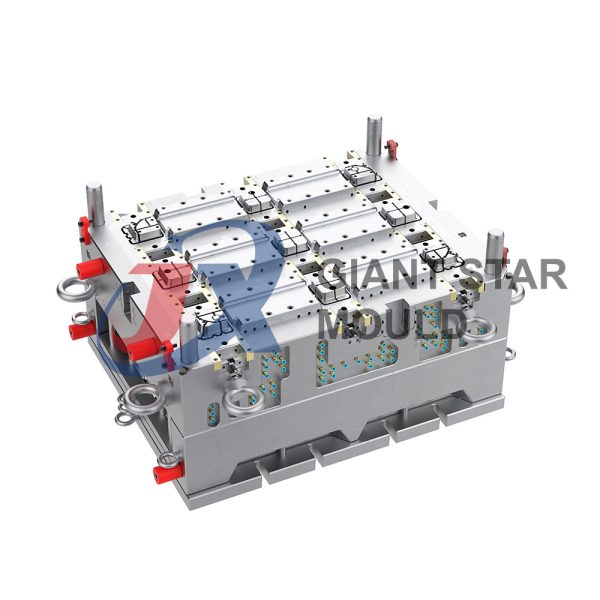

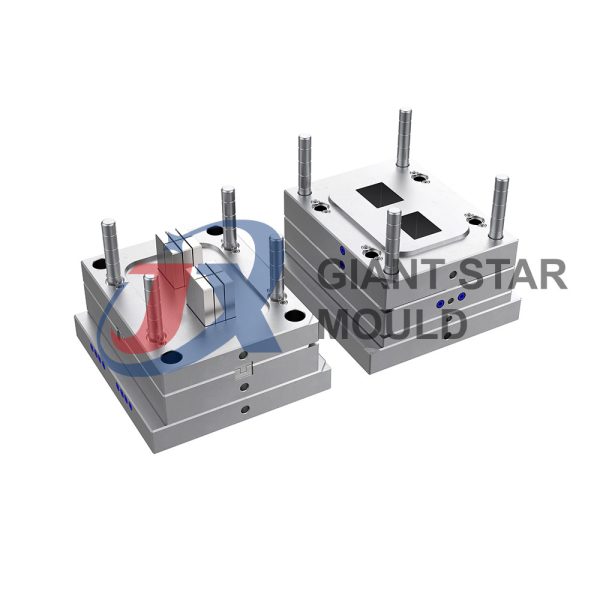

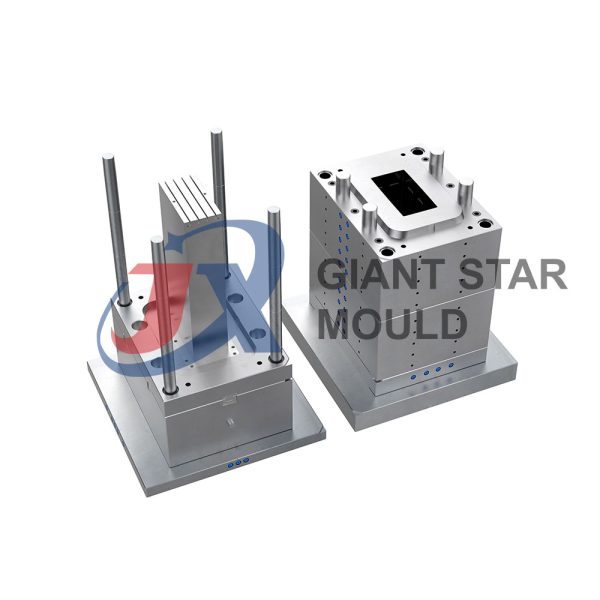

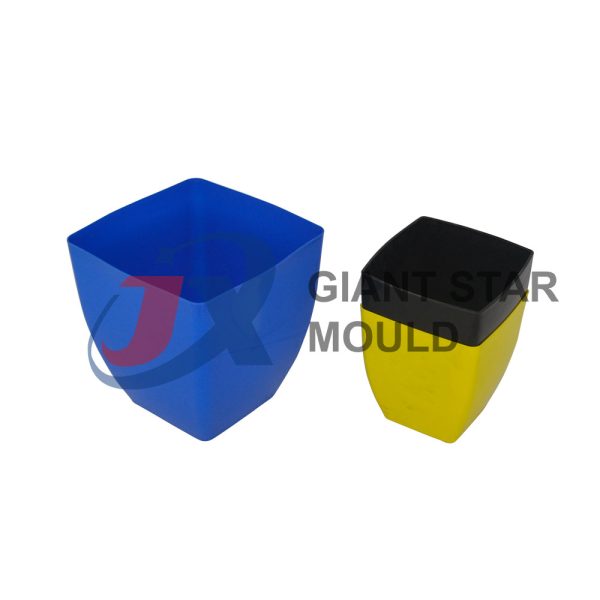

Battery Container Mould 32

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

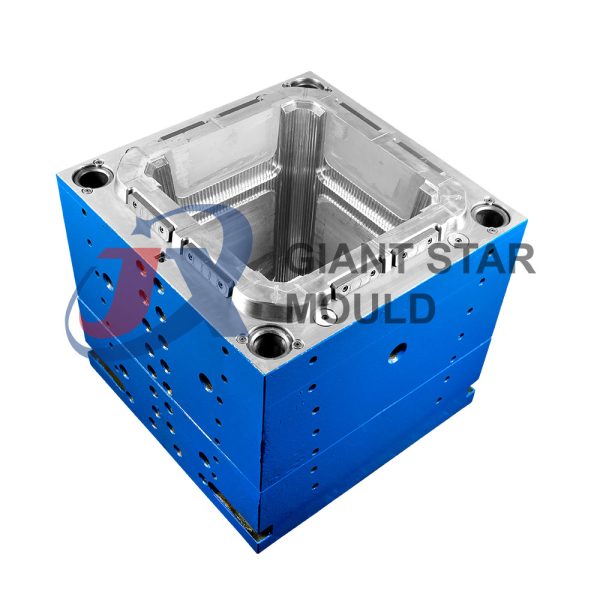

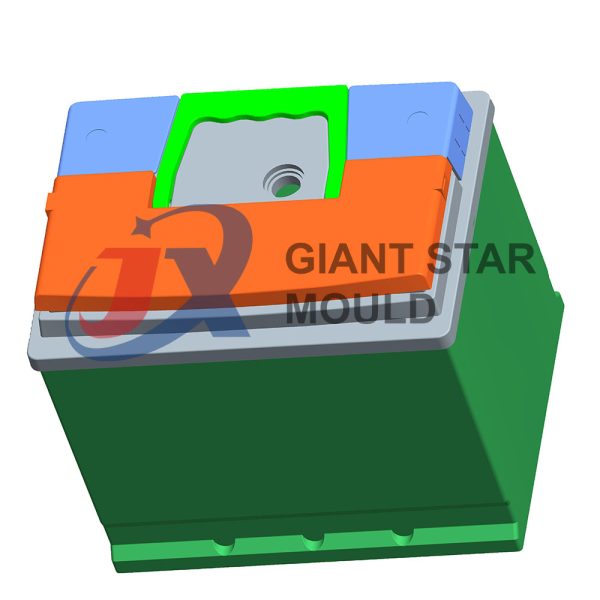

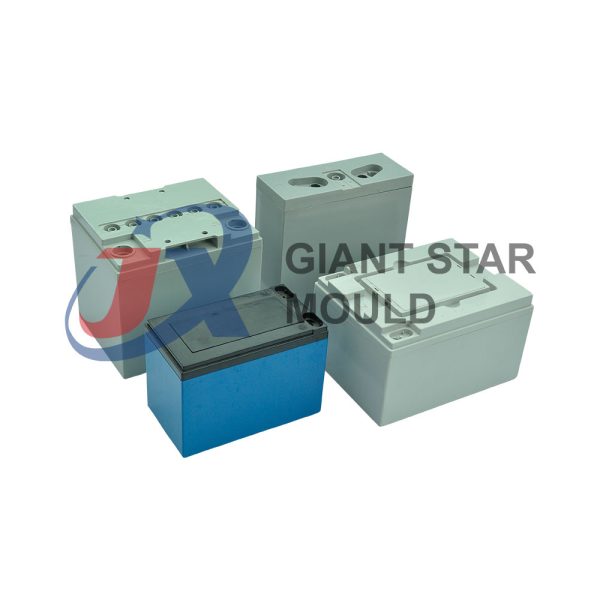

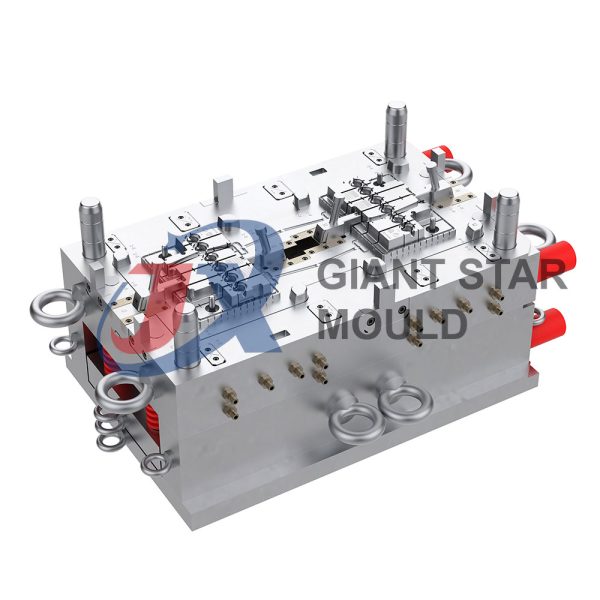

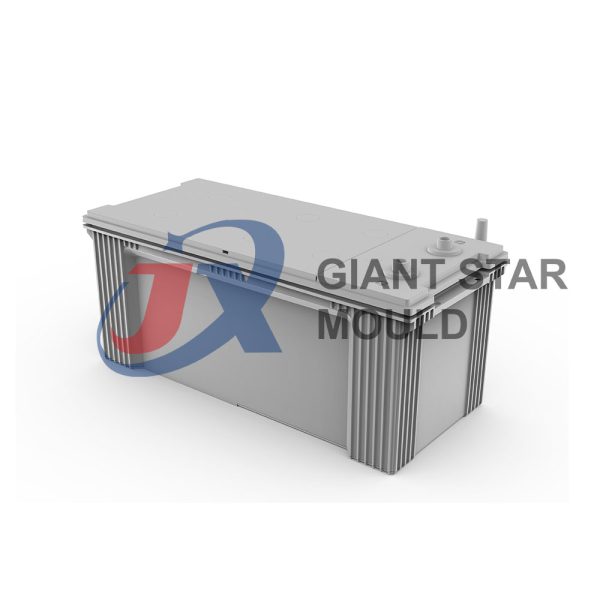

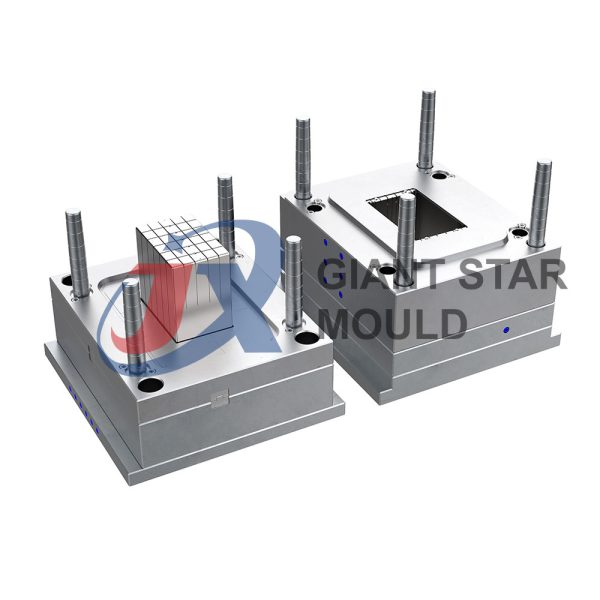

Battery Container Mould 31

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

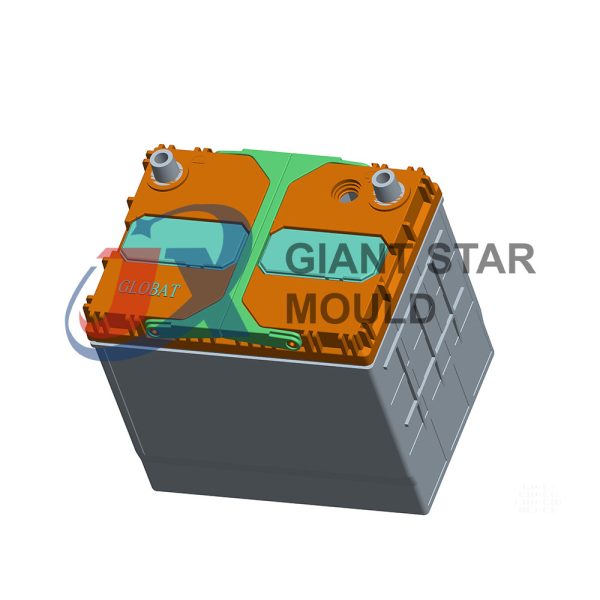

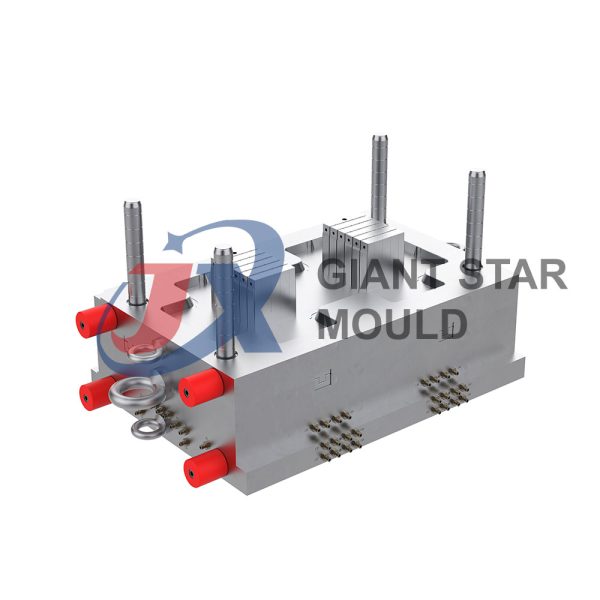

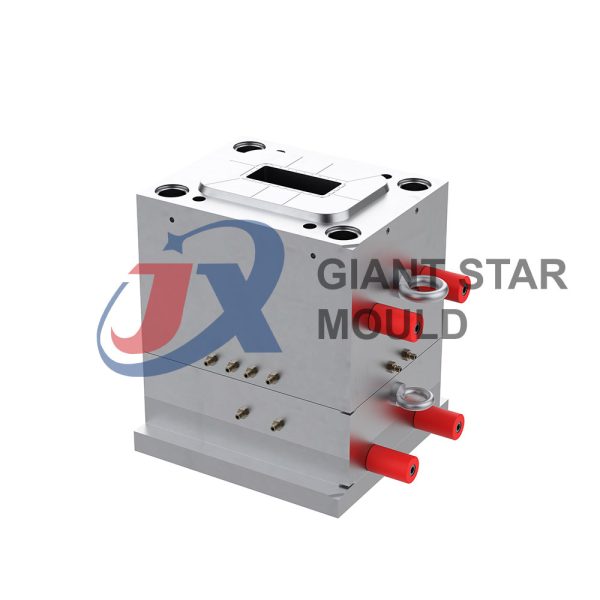

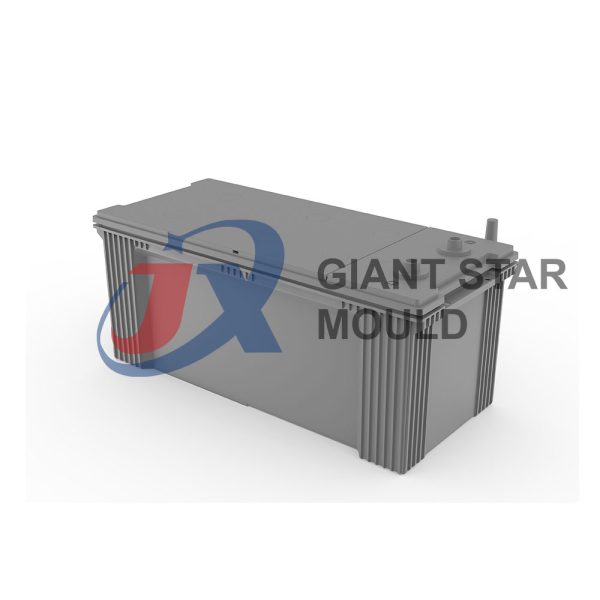

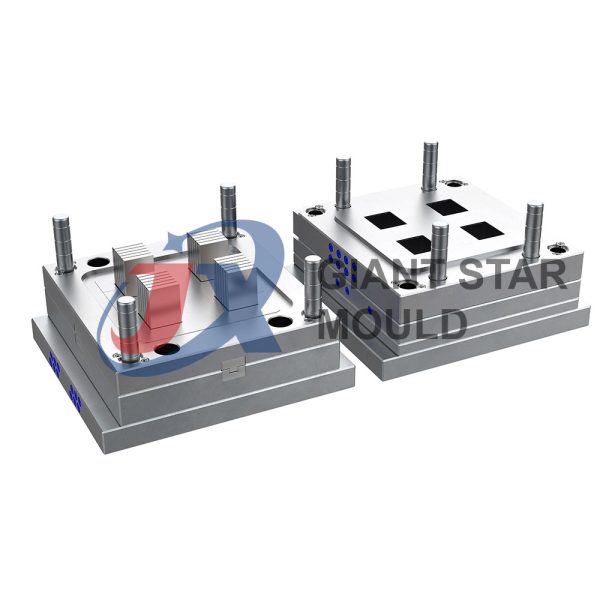

Battery Container Mould 30

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

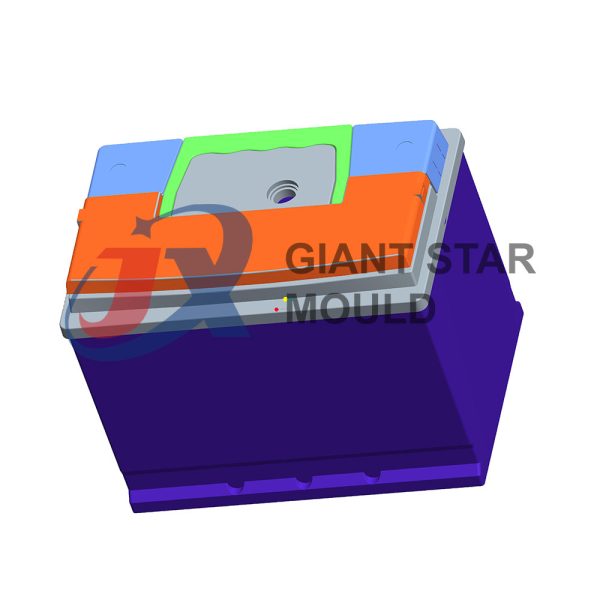

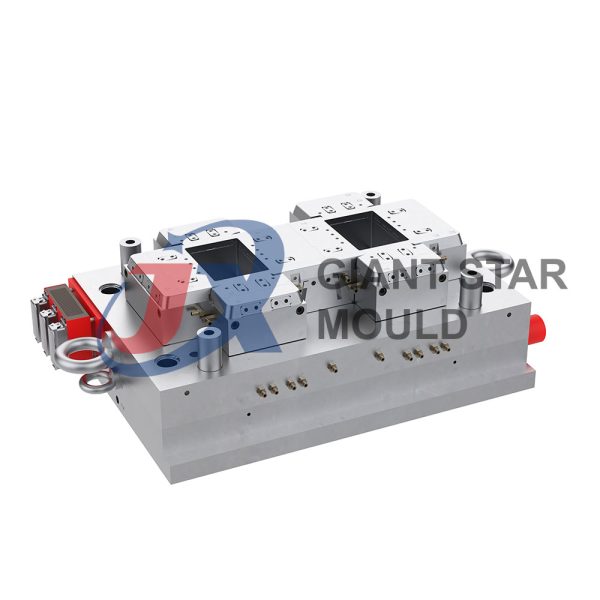

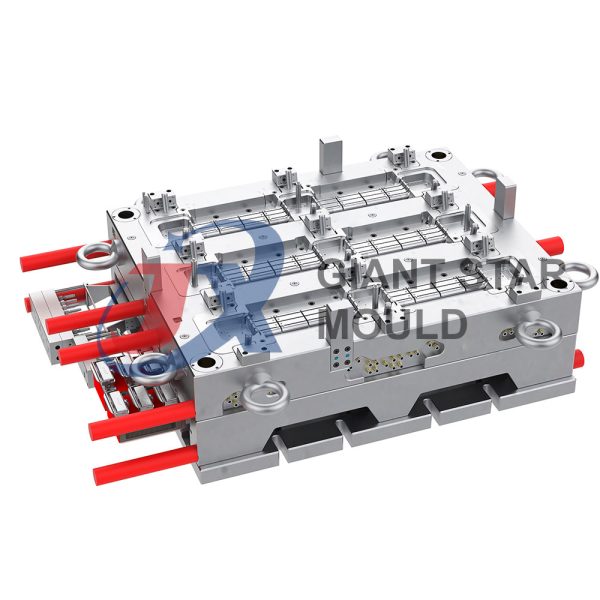

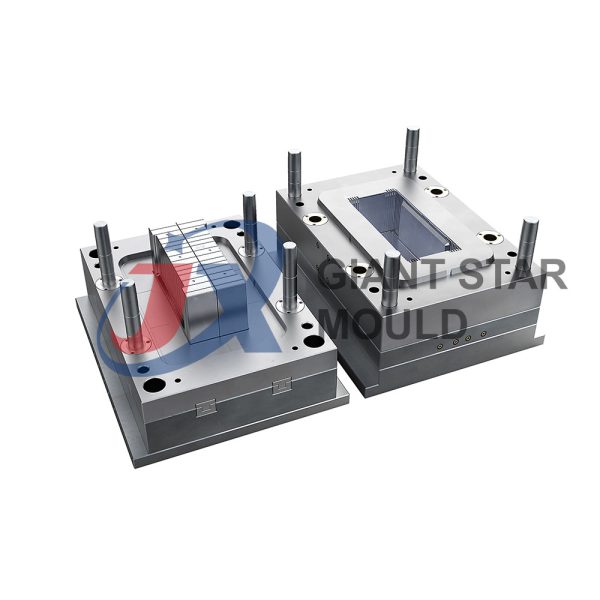

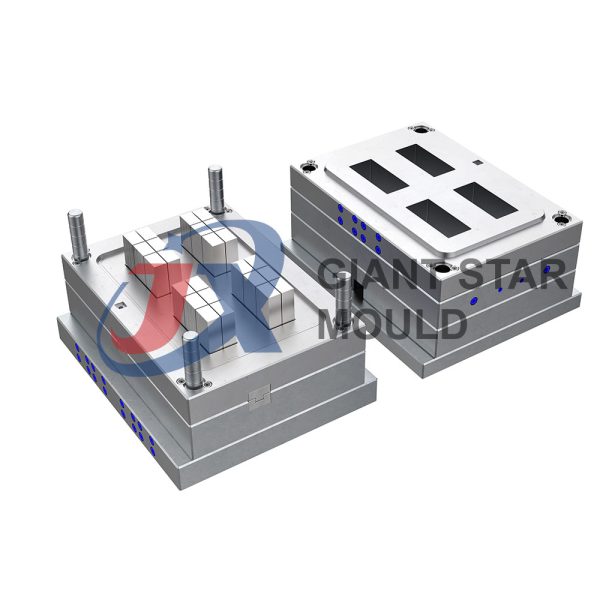

Battery Container Mould 29

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 28

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 27

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 26

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 25

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 24

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 23

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 22

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 21

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 20

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 19

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 18

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 17

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 16

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 15

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 14

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 13

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 12

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 11

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 10

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 09

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 08

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 07

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 06

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 05

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 04

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 03

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 02

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

Battery Container Mould 01

Creating a plastic battery container mold involves several steps and considerations. Here's a simplified overview of the process:

- Design: Begin with the design of the battery container. This can be done using CAD (Computer-Aided Design) software. The design should consider factors such as size, shape, material thickness, and any features required for assembly or functionality.

- Material Selection: Choose the appropriate plastic material for the battery container. Factors such as chemical resistance, mechanical properties, and cost should be taken into account.

- Mold Design: Once the container design is finalized, the mold design process begins. This involves designing the mold cavity, cores, runners, gates, and cooling channels. Mold design can also be done using CAD software, and it's crucial to ensure that the mold design allows for proper filling and cooling of the plastic material.

- Mold Fabrication: With the mold design complete, the next step is to fabricate the mold. This can be done through various methods such as CNC machining, EDM (Electrical Discharge Machining), or casting. The choice of method depends on factors such as complexity, tolerances, and budget.

- Injection Molding: Once the mold is fabricated, it's installed into an injection molding machine. Plastic pellets are fed into the machine's hopper, melted, and injected into the mold cavity under high pressure. The plastic material fills the cavity, taking the shape of the battery container.

- Cooling and Ejection: After the plastic material is injected into the mold, it needs to cool and solidify. Cooling channels within the mold help facilitate this process. Once the plastic is sufficiently cooled, the mold opens, and the newly formed battery container is ejected.

- Trimming and Finishing: The ejected battery container may have excess material or rough edges that need to be trimmed or finished. This can be done manually or using automated trimming equipment.

- Quality Control: Finally, the battery containers undergo quality control checks to ensure they meet specifications and standards. This may include dimensional checks, visual inspection, and testing for structural integrity.

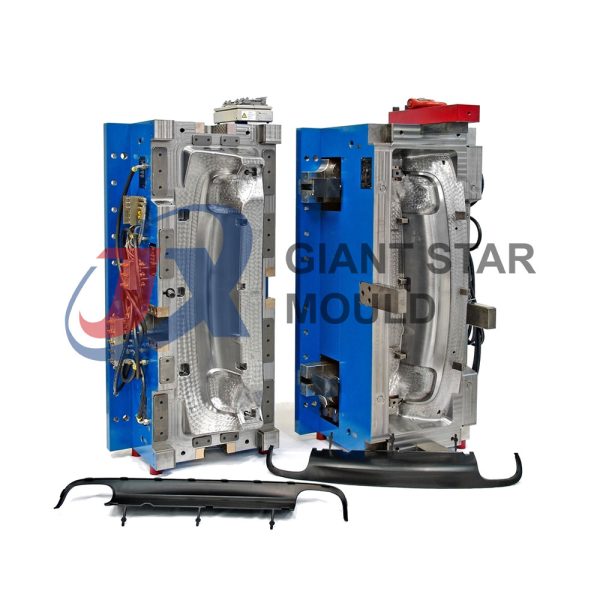

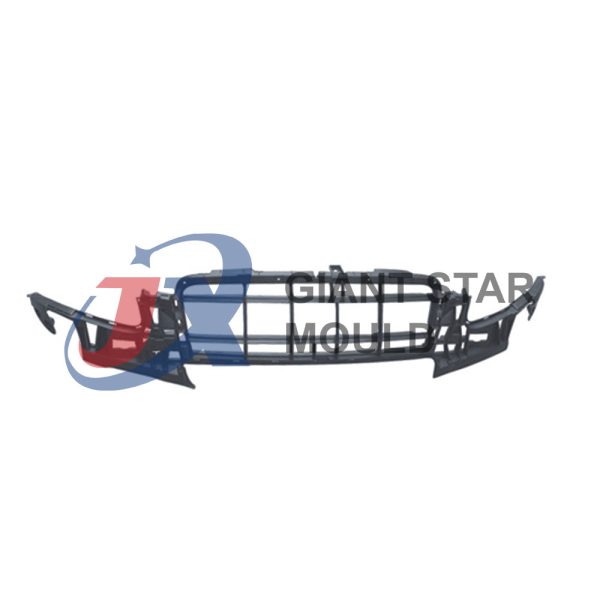

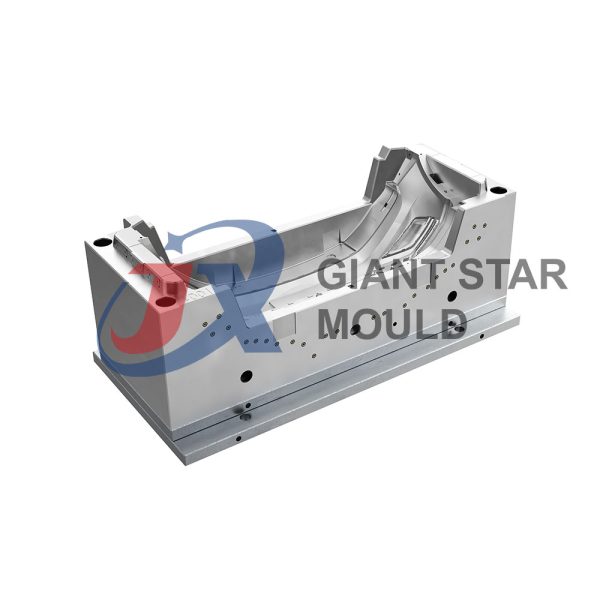

Automotive Mould 32

Giant star Mold is a professional maker for automotive molds, car molds, automobile molds and vehicle molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For automotive mold maker, we often give you this suggestion:

Core and cavity steel: Up to customer’s budget and productivity required, we suggest the following steel grade: Pre- harden steel : P20 (1.2311), P20+Ni…etc Harfen Steel : H13 (1.2344) / NAK80…etc. Stainless steel : ASSAB Stavax…etc

Steel of Mold Base:Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20

Hardness of Cavity & Core:Pre-Hardenss Steel : HRC 30~32+-1* Heat Treatment Steel : HRC 50~52+-1*

Core pulling or Ejection system: Depends on the Products. Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc

Mold Accessories: Compatible to DME/ HASCO Standard.

Cooling System:In Core : Baffle or By pass cooling ;In Cavity Plate: Chain drilling type cooling

Surface Finish: Up to the product’s requirement, Normal used : Texture, EDM machining , Polishing

Mold Life: Up to mold steel grade, under ideal operation condition, 1. Pre-harden steel, min. 20~300000 shots 2. Harden / heat treatment steel : 60~800000 shots. 3. Stainless steel : 1 million shots.

Runner: 1. Cold runner 2. Hot runner 3.cold runner +hot runner

Delivery time: 80~90 days , presenting T1 samples

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production

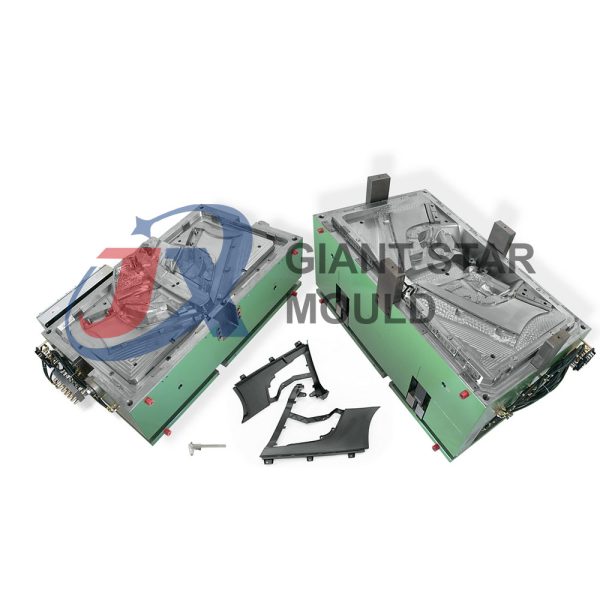

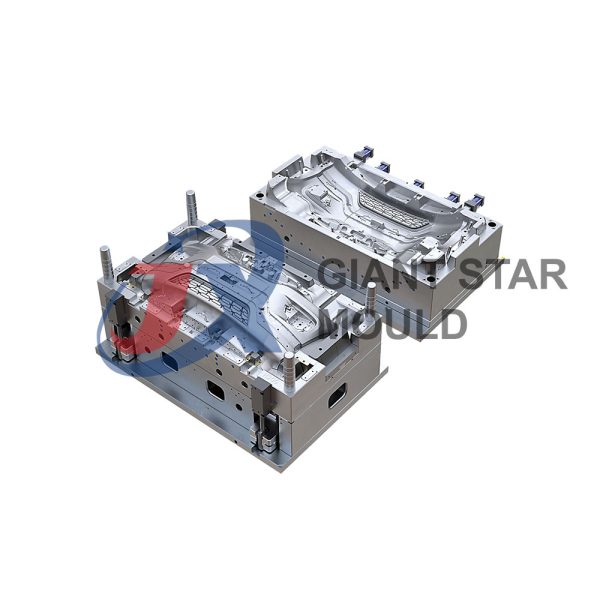

Automotive Mould 31

Giant star Mold is a professional maker for automotive molds, car molds, automobile molds and vehicle molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For automotive mold maker, we often give you this suggestion:

Core and cavity steel: Up to customer’s budget and productivity required, we suggest the following steel grade: Pre- harden steel : P20 (1.2311), P20+Ni…etc Harfen Steel : H13 (1.2344) / NAK80…etc. Stainless steel : ASSAB Stavax…etc

Steel of Mold Base:Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20

Hardness of Cavity & Core:Pre-Hardenss Steel : HRC 30~32+-1* Heat Treatment Steel : HRC 50~52+-1*

Core pulling or Ejection system: Depends on the Products. Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc

Mold Accessories: Compatible to DME/ HASCO Standard.

Cooling System:In Core : Baffle or By pass cooling ;In Cavity Plate: Chain drilling type cooling

Surface Finish: Up to the product’s requirement, Normal used : Texture, EDM machining , Polishing

Mold Life: Up to mold steel grade, under ideal operation condition, 1. Pre-harden steel, min. 20~300000 shots 2. Harden / heat treatment steel : 60~800000 shots. 3. Stainless steel : 1 million shots.

Runner: 1. Cold runner 2. Hot runner 3.cold runner +hot runner

Delivery time: 80~90 days , presenting T1 samples

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production

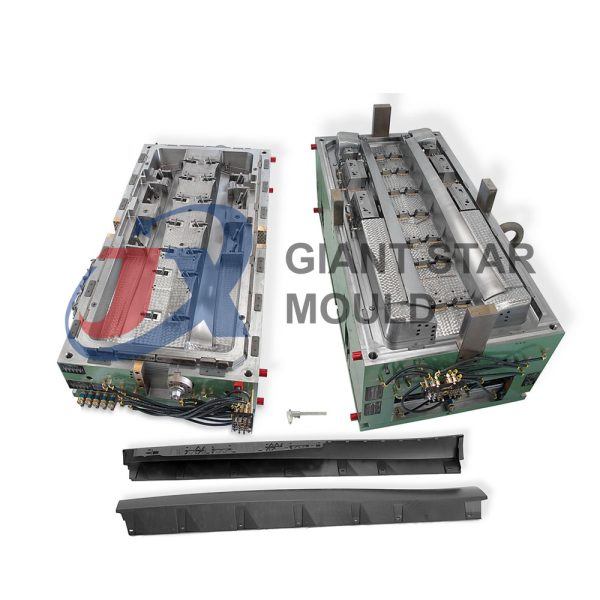

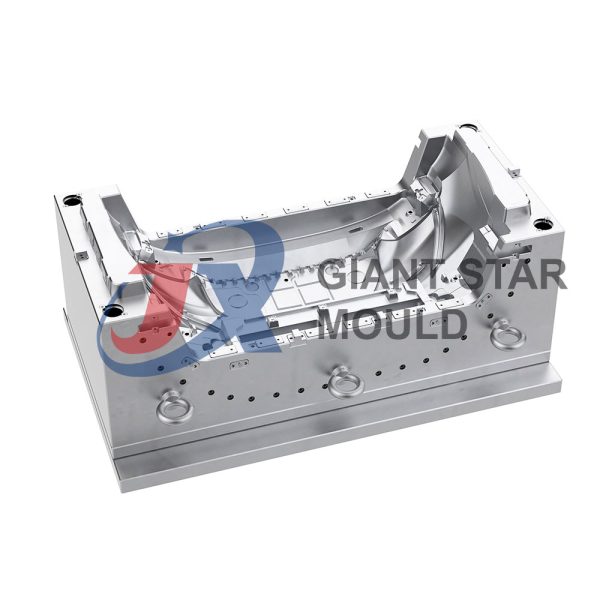

Automotive Mould 30

Giant star Mold is a professional maker for automotive molds, car molds, automobile molds and vehicle molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For automotive mold maker, we often give you this suggestion:

Core and cavity steel: Up to customer’s budget and productivity required, we suggest the following steel grade: Pre- harden steel : P20 (1.2311), P20+Ni…etc Harfen Steel : H13 (1.2344) / NAK80…etc. Stainless steel : ASSAB Stavax…etc

Steel of Mold Base:Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20

Hardness of Cavity & Core:Pre-Hardenss Steel : HRC 30~32+-1* Heat Treatment Steel : HRC 50~52+-1*

Core pulling or Ejection system: Depends on the Products. Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc

Mold Accessories: Compatible to DME/ HASCO Standard.

Cooling System:In Core : Baffle or By pass cooling ;In Cavity Plate: Chain drilling type cooling

Surface Finish: Up to the product’s requirement, Normal used : Texture, EDM machining , Polishing

Mold Life: Up to mold steel grade, under ideal operation condition, 1. Pre-harden steel, min. 20~300000 shots 2. Harden / heat treatment steel : 60~800000 shots. 3. Stainless steel : 1 million shots.

Runner: 1. Cold runner 2. Hot runner 3.cold runner +hot runner

Delivery time: 80~90 days , presenting T1 samples

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production

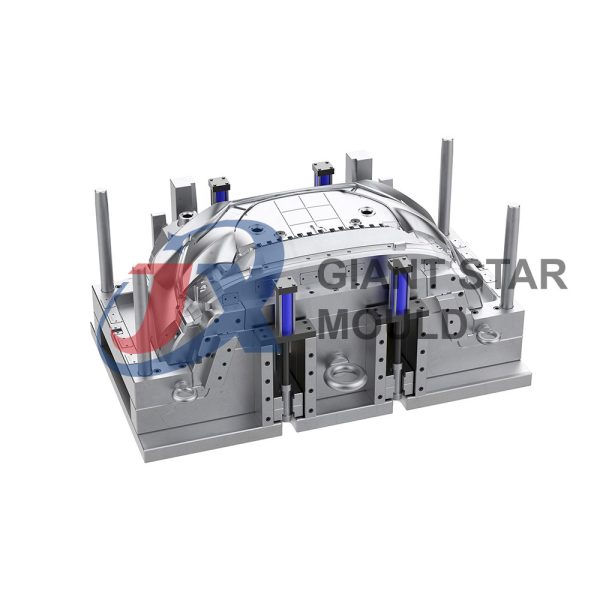

Automotive Mould 29

Giant star Mold is a professional maker for automotive molds, car molds, automobile molds and vehicle molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For automotive mold maker, we often give you this suggestion:

Core and cavity steel: Up to customer’s budget and productivity required, we suggest the following steel grade: Pre- harden steel : P20 (1.2311), P20+Ni…etc Harfen Steel : H13 (1.2344) / NAK80…etc. Stainless steel : ASSAB Stavax…etc

Steel of Mold Base:Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20

Hardness of Cavity & Core:Pre-Hardenss Steel : HRC 30~32+-1* Heat Treatment Steel : HRC 50~52+-1*

Core pulling or Ejection system: Depends on the Products. Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc

Mold Accessories: Compatible to DME/ HASCO Standard.

Cooling System:In Core : Baffle or By pass cooling ;In Cavity Plate: Chain drilling type cooling

Surface Finish: Up to the product’s requirement, Normal used : Texture, EDM machining , Polishing

Mold Life: Up to mold steel grade, under ideal operation condition, 1. Pre-harden steel, min. 20~300000 shots 2. Harden / heat treatment steel : 60~800000 shots. 3. Stainless steel : 1 million shots.

Runner: 1. Cold runner 2. Hot runner 3.cold runner +hot runner

Delivery time: 80~90 days , presenting T1 samples

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production

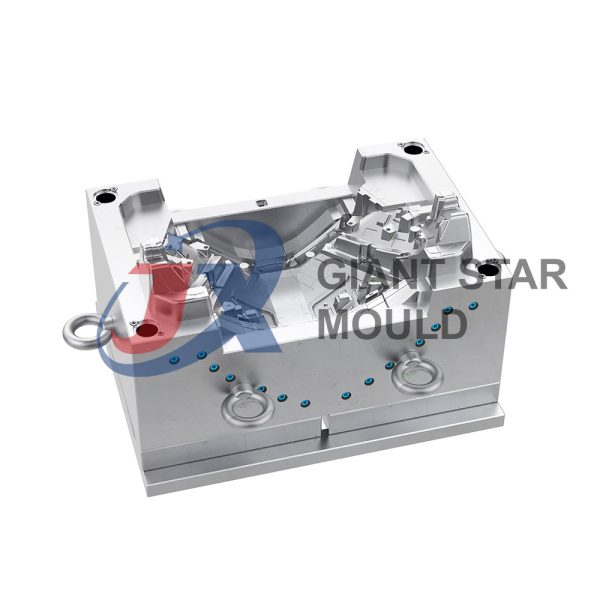

Automotive Mould 28

Giant star Mold is a professional maker for automotive molds, car molds, automobile molds and vehicle molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For automotive mold maker, we often give you this suggestion: